Advantages and disadvantages of compression moulding

Posted on 27/04/2014 Category: Technical Features

What Is Compression Moulding?

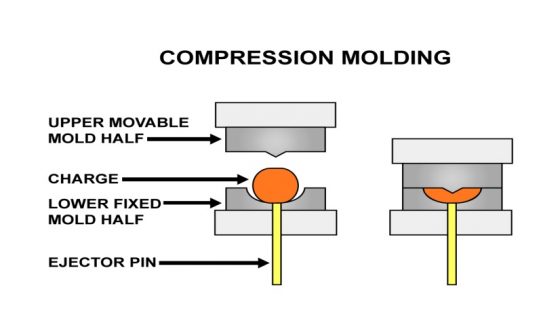

The compression moulding process combines heat and pressure to mould thermoset rubber or plastic resin into the customer’s desired shape. The resin or rubber material is shaped using a heated mould tool and the clamping pressure of a press to force the flow of that material around inside the tool. This process instigates the thermoset characteristic of the material, and permanent chemical change takes place, fixing the product’s shape.

Once this cure or vulcanisation process is complete, the mould is opened, and the part is extracted and allowed to cool, maintaining the shape of the mould that produced it, although the part may shrink during cooling to arrive at its final size. The technique can make various products, such as Wellington boots, machinery parts, rubber seals, custom gaskets, or even door stops and chair feet.

This manufacturing process can reproduce the same product many times, but it is not necessarily suitable for everything. Here are some advantages and disadvantages of compression moulding as a process to help you decide if it’s right for you and your product.

Advantages of Compression Moulding:

Lower-cost Tooling

The process does not involve an injection or transfer cycle; the tooling has fewer infrastructure requirements than tools designed for other rubber moulding methods. Other than the particular features of the cavity that will produce the moulded parts, which have to replicate the product’s detail, there is little else needed in the way of additional features. Tools can be made of aluminium or lower-cost steel grades, which can save cost, although any tool must withstand the considerable moulding pressures required.

Good for small production runs

The lower capital cost of manufacturing a mould tool, setting up a press, and beginning to run production parts means that compression moulding is the most cost-effective method for making smaller parts runs. There is, of course, a breakeven point where the higher capital cost of an injection mould tool becomes viable due to the lower cost of the parts it makes, and making the correct determination of this point is a key consideration when developing the best production solution for a new product.

No gates, sprues or runners

This form of moulding does not use gates, sprues, or runners, which are tooling features that materials have to pass through in other production methods before entering the mould cavity. These consume extra material and, therefore, cost, and can also detract from the cosmetic requirements of a part, both of which can be considerations when deciding the most appropriate tooling method for production.

Good for large parts

This form of moulding is particularly suited to producing large parts, which require a significant bulk of material to manufacture. Because the material is loaded into the mould cavity directly, there is no limitation on the weight of the part that can be made other than the press size and tonnage required. In contrast, injection moulding presses are limited in the weight of the part they can produce by the volume of the injection barrel that fills the mould.

Disadvantages of Compression Moulding:

Greater waste

Compression moulding is not as precise a product as injection moulding because the mould cavity has to be overfilled to some degree to achieve the correct pressure to cure the part. It is also often necessary to push air out of the cavity using excess material to create a void-free part, increasing waste. In contrast, an injection mould is more precisely filled and inherently drives out the air as it is filled. Waste thermoset rubber or plastic cannot be melted down and reused, so the part’s cost must reflect this.

Higher labour cost

This production technique is simple but requires more manpower than a semi-automatic injection moulding process to run. The skill level is often proportionately higher, and manual handling can become an issue for more significant parts or tools.

Slower process times

Due to the thermal conductivity of rubber and resin being relatively poor, bringing a blank of material up to curing temperature by contact with the hot surfaces of the mould does take time for larger parts, and this limits the speed at which parts can be cured and de-moulded. Injection moulding, however, shoots material into the mould already at a temperature just below curing, so the extra time required to begin curing once the press closes is much shorter. A typical cycle may take around ten minutes, depending on the part size, whereas the equivalent injection moulding cycle would take about five minutes. This can make a significant difference when producing parts in higher volumes when production rate and part cost become the priority.

Not suitable for complex moulds

While complex parts can be made by compression moulding, depending on the material required and the specifics of the design, it is generally better suited to producing larger, simpler objects. This is because the limited flow of material within the cavity often makes eliminating voids, air traps, and knit lines difficult when trying to produce complex parts.

Contamination

It is much easier to produce clean, consistently coloured rubber parts by injection or transfer moulding, as the uncured blank compound used in compression moulding can pick up specks of dirt, which then simply get pressed and cured into the surface of the part and result in poor cosmetic appearance despite the part being dimensionally and physically acceptable. This increases reject rates and waste.

Difficult to control flash

Flash is a necessary by-product of compression moulding due to the need to expel air during the moulding process by overfilling the mould cavity. This flash can also vary in thickness depending on the exact fill of each particular shot, leading to issues with variable dimensions of the part over the split line (see our tolerance guide relating to BS3734.)

The flash must be mechanically cut off and, again, is a thermoset material that cannot be recycled easily, and the resulting split line witness mark is often more evident than on an injection-moulded part, which may be an aesthetic problem to the customer. Generally, compression-moulded parts require more labour to trim and finish, increasing the cost.

Moulds can be damaged

The repetitive nature of this process means that the moulds themselves can become victims of general wear and tear with manually loaded material blanks. Often, the mould is made to run loose and not bolted into a press. This can lead to the deterioration of trim grooves and fine details or, in extreme cases, impact damage on mould faces caused by poor handling. Overall, compression moulding is ideal when used appropriately and can help keep overall project costs to a minimum. However, individual part costs will be higher compared to other techniques.

Find the Compression Moulding Solution for Your Application

It is vital to consider all the required aspects of a product, its performance, and its life cycle when designing the most appropriate production solution, as each processing technique has different costs and benefits. The proper solution may not require an expensive injection moulding tool, and thus, even if the part cost is higher, compression-moulded solutions remain as relevant as ever.

If you have any questions about whether a compression moulding solution fits your application, be sure to contact us, and a member of our team will be happy to help. Explore our technical articles on rubber shrinkage and hardness and our Moulding Expertise webpage for more information.